CNC machine parts

HMI & PLC

Electrical devices

Posts

Bending&shearing controller

type

status

date

slug

summary

tags

category

icon

password

📙Model & price

ESTUN E21 press brake controller

- only ESTUN E21 [$215][Currency]

- only encoder [$35][Currency]

- ESTUN E21 full set[$350][Currency]

ESTUN E21s shearing controller

- only ESTUN E21s [$215][Currency]

- only encoder [$35][Currency]

- ESTUN E21s full set[$350][Currency]

📙Product description

ESTUN E21 press brake controller

Product introduction:ESTUN E21 controller is an entry-level CNC system designed by ESTUN Automation, a Chinese company known for a variety of industrial automation products. The E21 system is specifically developed for bending applications and is commonly used in press brakes for sheet metal forming processes.The ESTUN E21 controller is a strategic choice for those seeking to optimize their press brake operations without incurring high costs. Through its smart features and easy-to-use interface, users can expect to benefit from consistent precision, less downtime, and increased productivity in their metal forming activities. Whether the task is simple or complex, the E21 stands as a reliable and cost-effective control solution.

Features:

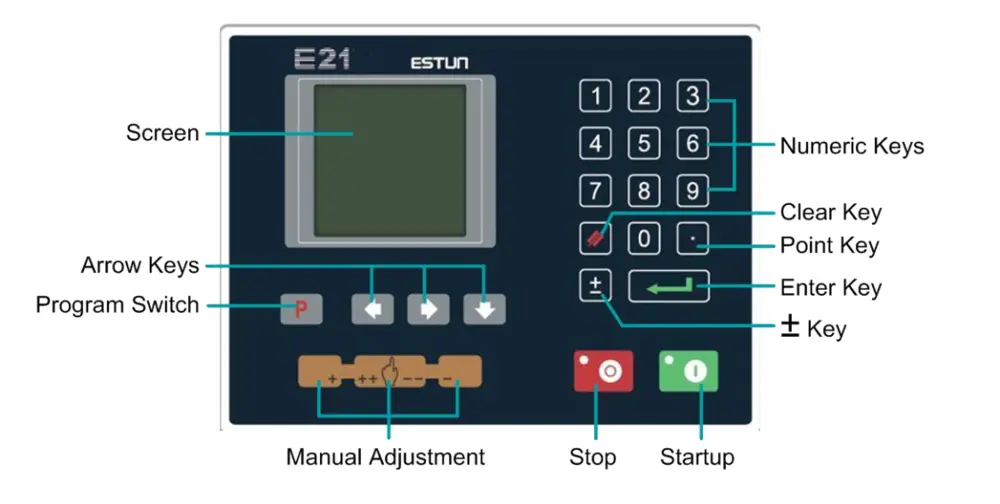

- User-Friendly Interface: The E21 has a simplistic and user-friendly interface that allows operators to input programming instructions with ease. It usually includes an LCD screen that displays real-time information.

- Support for Multiple Languages: It typically supports several languages, making it accessible for users worldwide.

- Control Functions: The controller provides basic control of the Y-axis and X-axis, enabling operators to manage the backgauge and ram efficiently. It often includes a manual, semi-automatic, and full-automatic mode for bending operations.

- Programming Capabilities: Even being an entry-level controller, the E21 allows for relatively straightforward programming for job executions. It can store up to 40 programs, each with up to 25 steps.

- Backgauge Control: The system offers precise control of the backgauge, which can improve the bending accuracy and quality of the final product.

- Bending Counting: It provides a useful function to count workpieces, helping operators track production.

- Tool Library: The E21 comes with a simple tool library for the user to select and configure tooling, essential for setting up the bending process.

- Parameters Backup and Restore: The controller allows users to back up and restore parameters, ensuring essential settings are retained and can be retrieved when necessary.

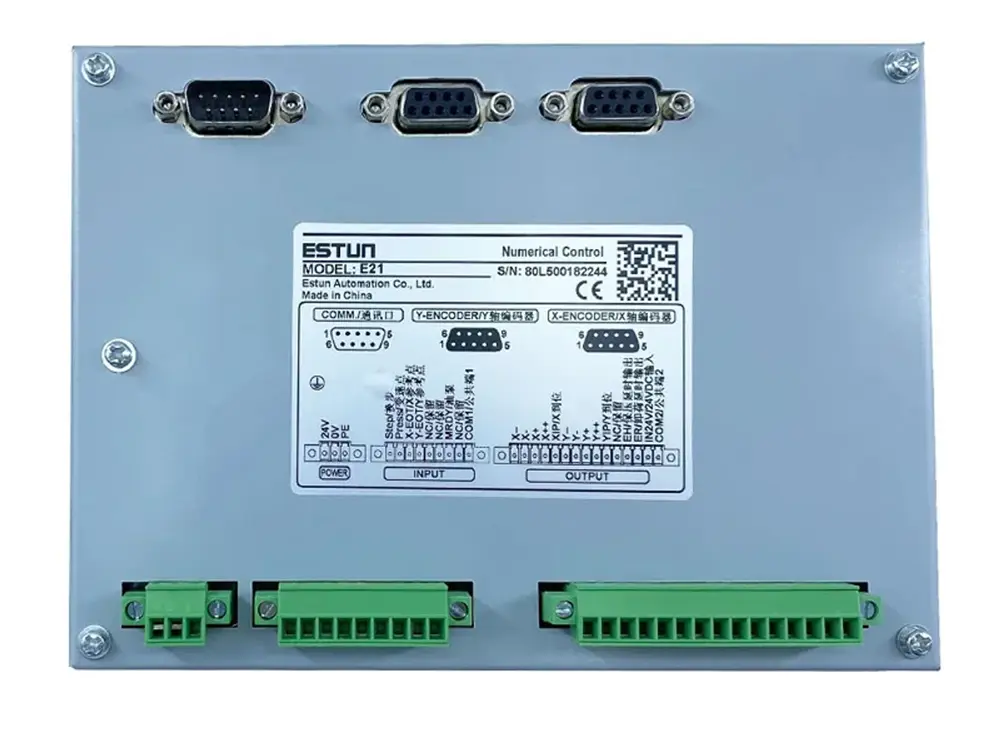

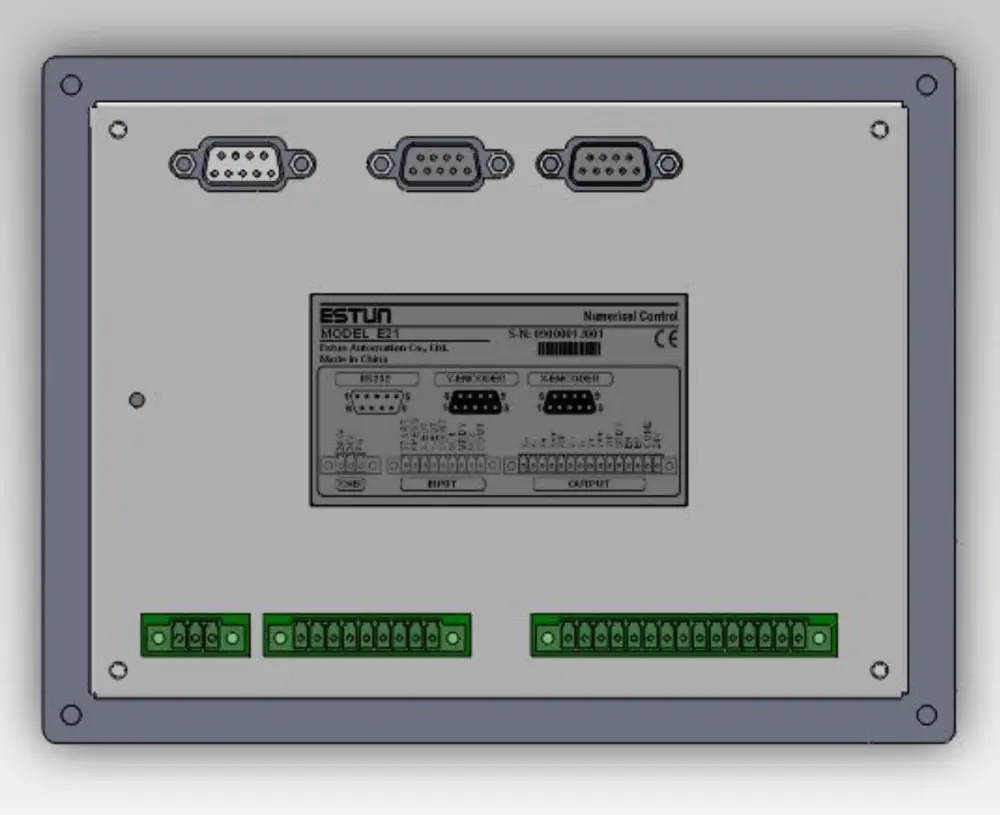

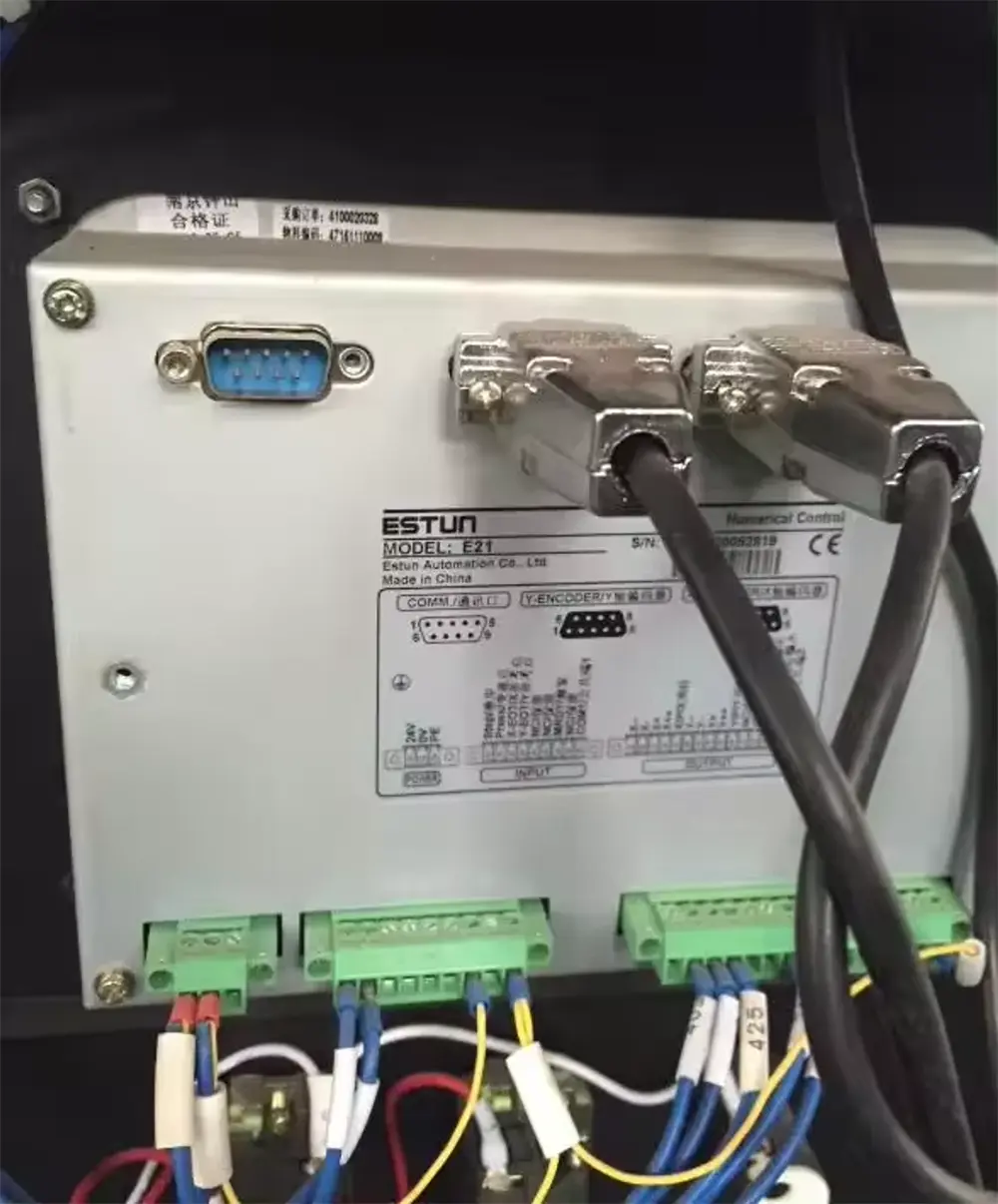

- USB Interface: For ease of data transfer, the E21 often includes a USB interface, enabling users to import and export programs and operate parameters.

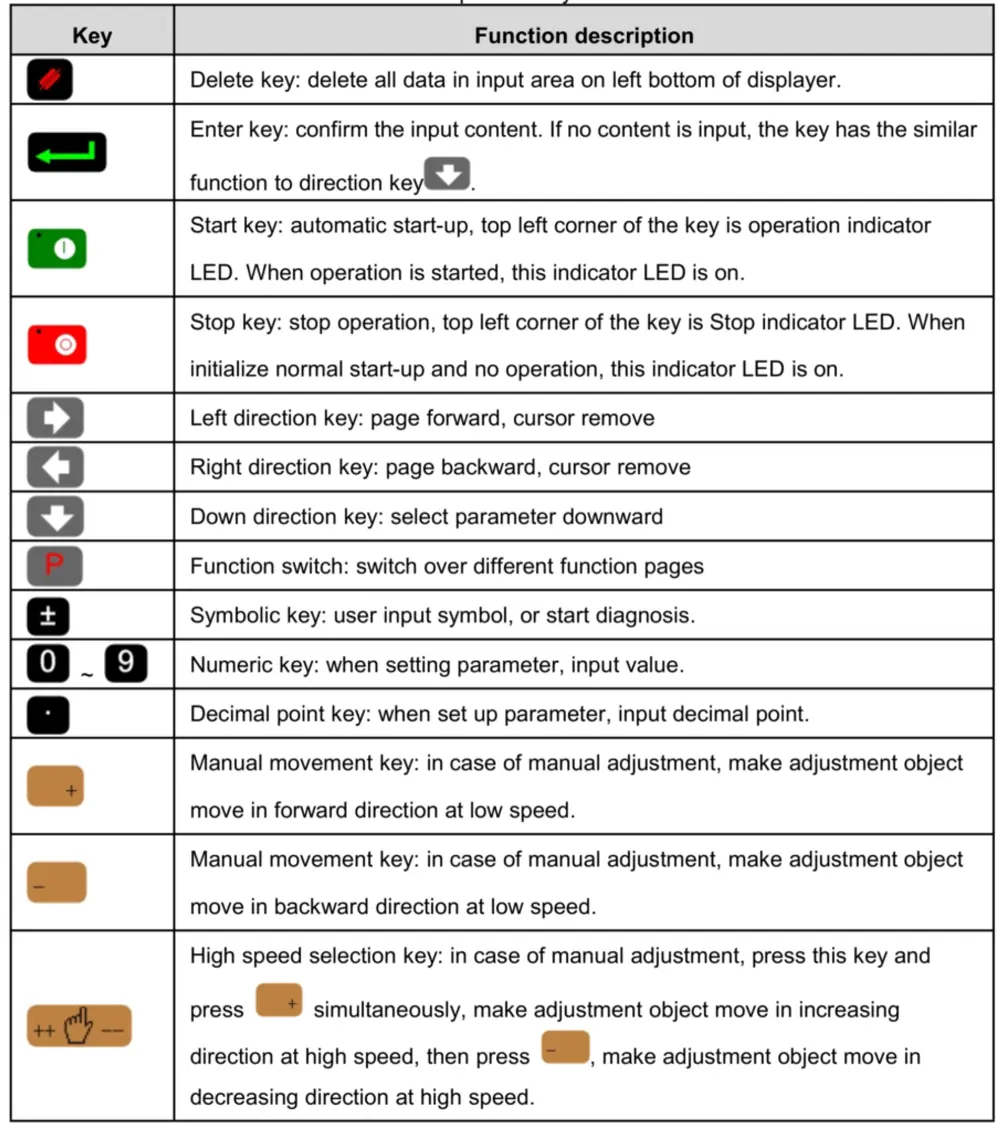

Description of key functions

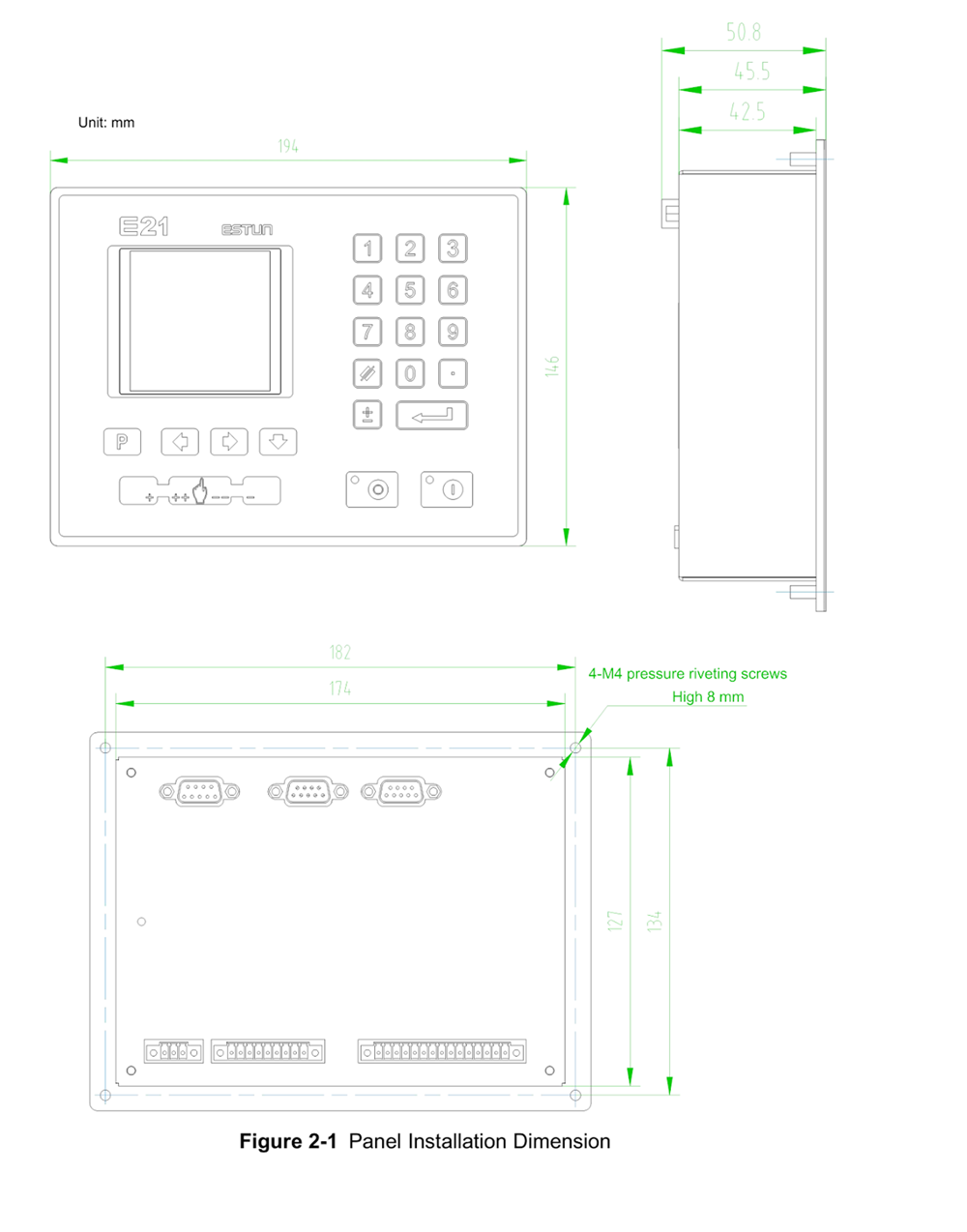

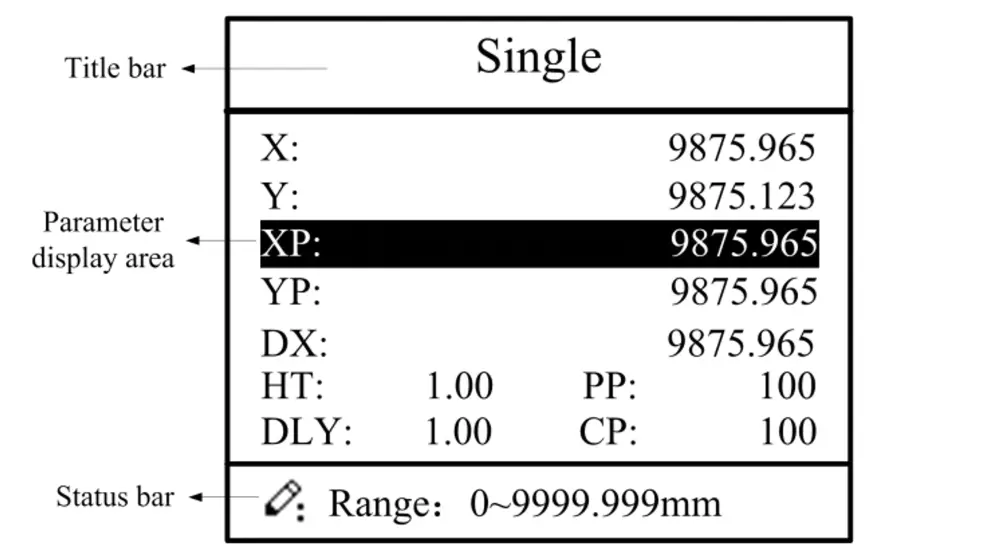

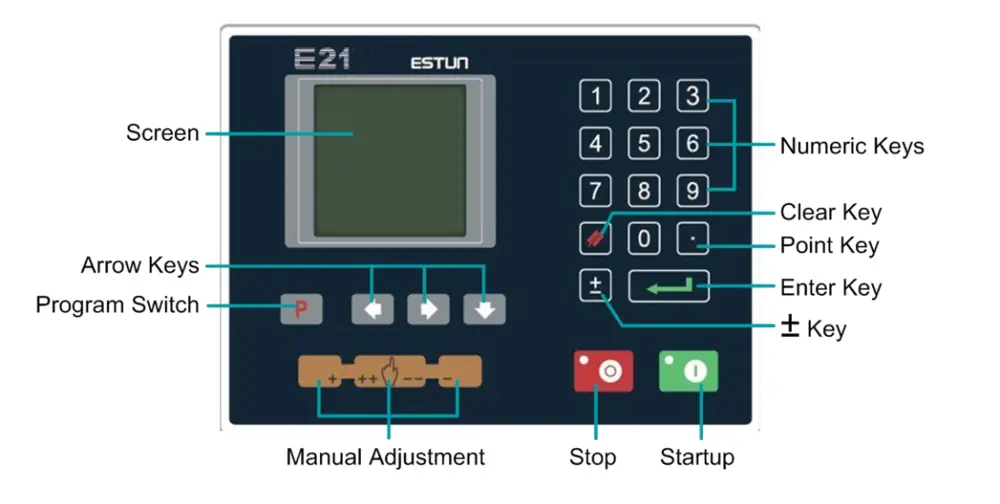

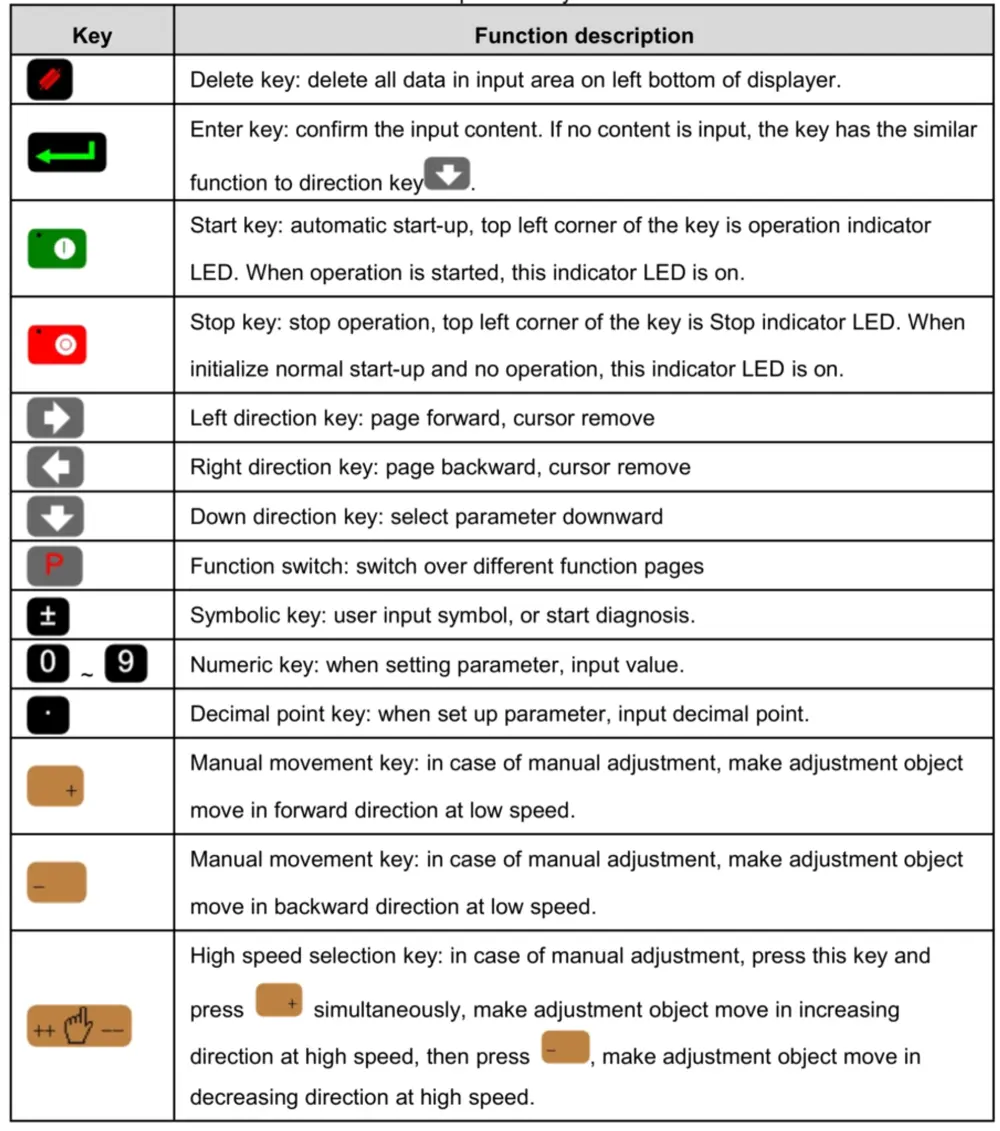

E21 numerical control device adopts 160*160 dot matrix LCD displayer.

- Title bar: display relevant information of current page, such as its name, etc.

- Parameter display area: display parameter name, parameter value and system

information.

- Status bar: display area of input information and prompt message, etc.

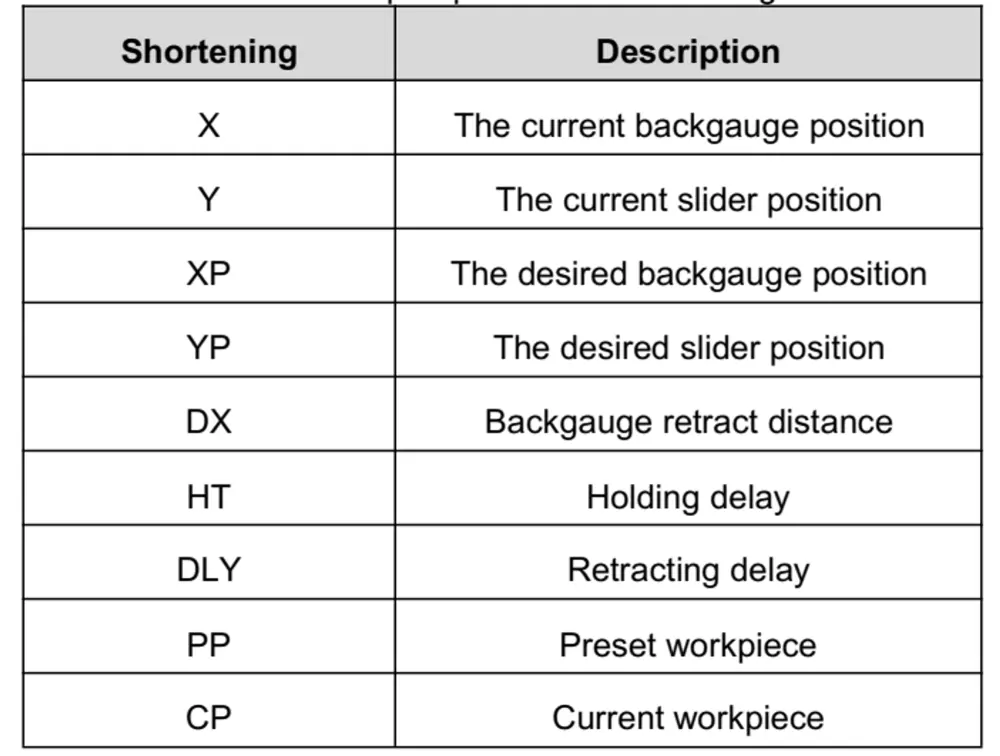

The paraphrases of shortening

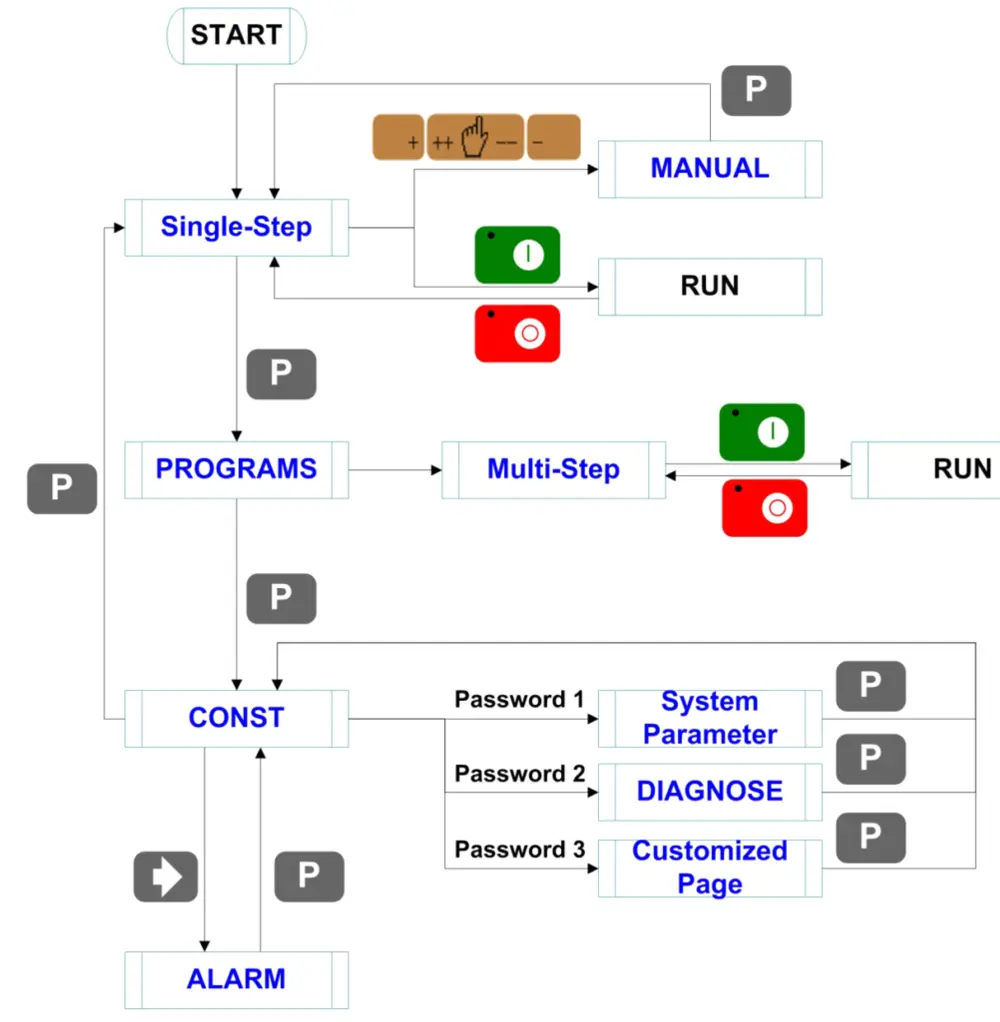

The ESTUN E21 press brake controller has a straightforward operation procedure. Here are the basic steps:

- Power On: Ensure the press brake controller is properly connected to the power supply and switch it on.

- Select Mode: The E21 controller offers several modes, such as manual mode and automatic mode. Select the desired mode based on your requirements.

- Set Parameters: Enter the necessary parameters for your bending operation. These parameters include material thickness, bending angle, and back gauge position.

- Manual Mode Operation: If you choose the manual mode, you can control the press brake manually using the control buttons. Use the foot pedal or the control panel to adjust the position of the press brake and perform the bending operation.

- Automatic Mode Operation: In automatic mode, the press brake controller utilizes pre-programmed bending sequences. Load the corresponding program for your specific bending task, and the controller will execute the bending process automatically.

- Fine-Tuning: The E21 controller allows you to adjust and fine-tune various parameters during the bending process. This includes modifying the back gauge position, bending speed, and angles if needed.

- Safety Measures: Always prioritize safety when operating the press brake. Ensure that the workpiece is properly secured, and operators follow all safety guidelines and precautions.

Remember, this is a basic overview of the ESTUN E21 press brake controller’s operation procedure. For detailed instructions, consult the user manual provided by the manufacturer or seek guidance from an expert.

ESTUN E21s shearing controller

Product introduction:This product is equipped with the shear machine dedicated numerical control device which is applicable to various users. Based on ensuring work precision, the cost of numerical control shearing machine is reduced significantly.

Features of this product are listed below:

- Back gauge can be controlled.

- Cut-angle can be controlled.

- Cut-gap can be controlled.

- Stroke time can be controlled.

- Intelligent positioning control.

- Unilateral and bidirectional positioning which eliminates spindle clearance effectively.

- Retract functions. Automatic reference searching.

- One-key parameter backup and restore.

- Fast position indexing. 40 programs storage space, each program has 25 steps.

- Power-off protection.

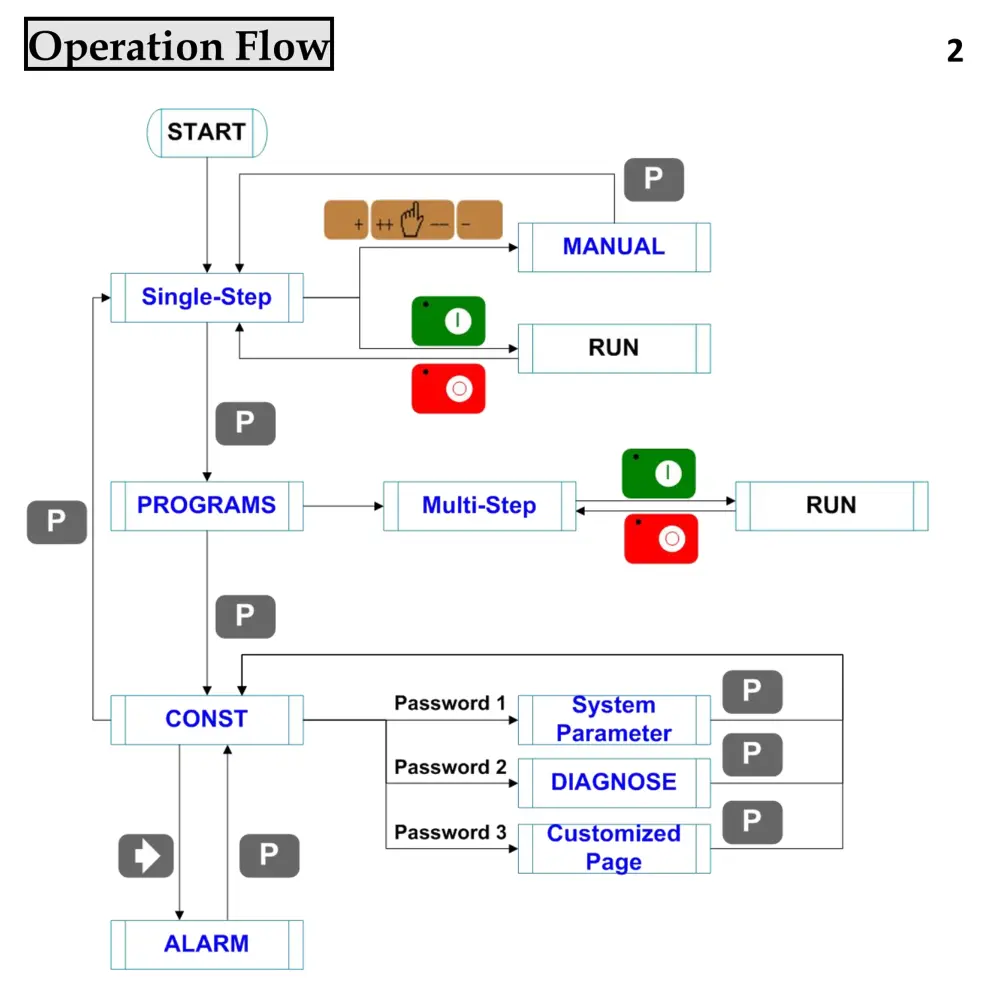

Single-Step Description:

- The default page is SINGLE; also, you can press the P key several times, switching to the SINGLE page.

- Press Arrow Keys to select the parameter you want to program.

- Press Numeric Keys to program a desired value.

- Press Enter Key to complete the setting.

- Follow the above methods to program the other parameters.

- After finishing the program, press Startup Key to run the device.

Last update: 2024